- +33 877 554 332

- info@veritasglobalcertification.com

HACCP

Hazard Analysis Critical Control Point

HACCP Certification

Hazard Analysis Critical Control Point (HACCP) techniques are increasingly being used in the food industry and are become a universally accepted method for food safety assurance. The UK’s Food Standards Agency recommends HACCP as the most effective way for food businesses to ensure consumer protection.

The HACCP principles developed by the Codex Alimentarius of the World Health Organisation demand that effective food safety systems are established through the application of systematic approach to hazard and risk analysis.

Increasingly companies within the food chain must be able to demonstrate an effective HACCP system, depending on varying local and national requirements. Meeting local food hygiene regulations and applying hazard analysis techniques, such as HACCP, add to what may already seem to be a complex and daunting process for those in the food chain.

However, taking a formalised approach to assuring food safety helps a company to demonstrate commitment by meeting the demands of legislation and customers and may support a due diligence defence.

Why HACCP Important For Business?

To be effective, the HACCP must be prepared specifically for each manufacturing process, following the seven basic steps prescribed by the UN:

- Execution of a Hazard-Analysis

- Identification of Critical Control Points

- Determination of limit values for each CCP

- Introduction of CCP monitoring procedures

- Determination of corrective actions

- Introduction of procedures to ensure the HACCPs error-free operation

- Establish record keeping procedures

Benefits of HACCP

- Saves your business money in the long run

- Avoids you poisoning your customers

- Food safety standards increase

- Ensures you are compliant with the law

- Food quality standards increase

- Organizes your process to produce safe food

- Organizes your staff promoting teamwork and efficiency

- Due diligence defense in court.

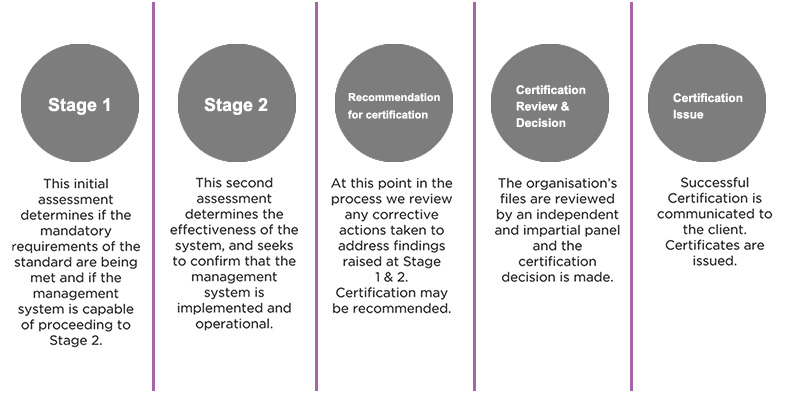

Certification Journey